The new dual sport helmet by Icaro

Certification for snow sports (EN 1077) and airborne sports (EN 966)

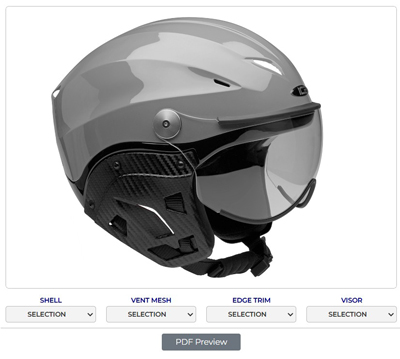

New helmet configurator

You can select from a series of options and view the helmet's final appearance.

Click on the button "PDF Preview" and send us the file; we will send you an immediate quote.

Introduction

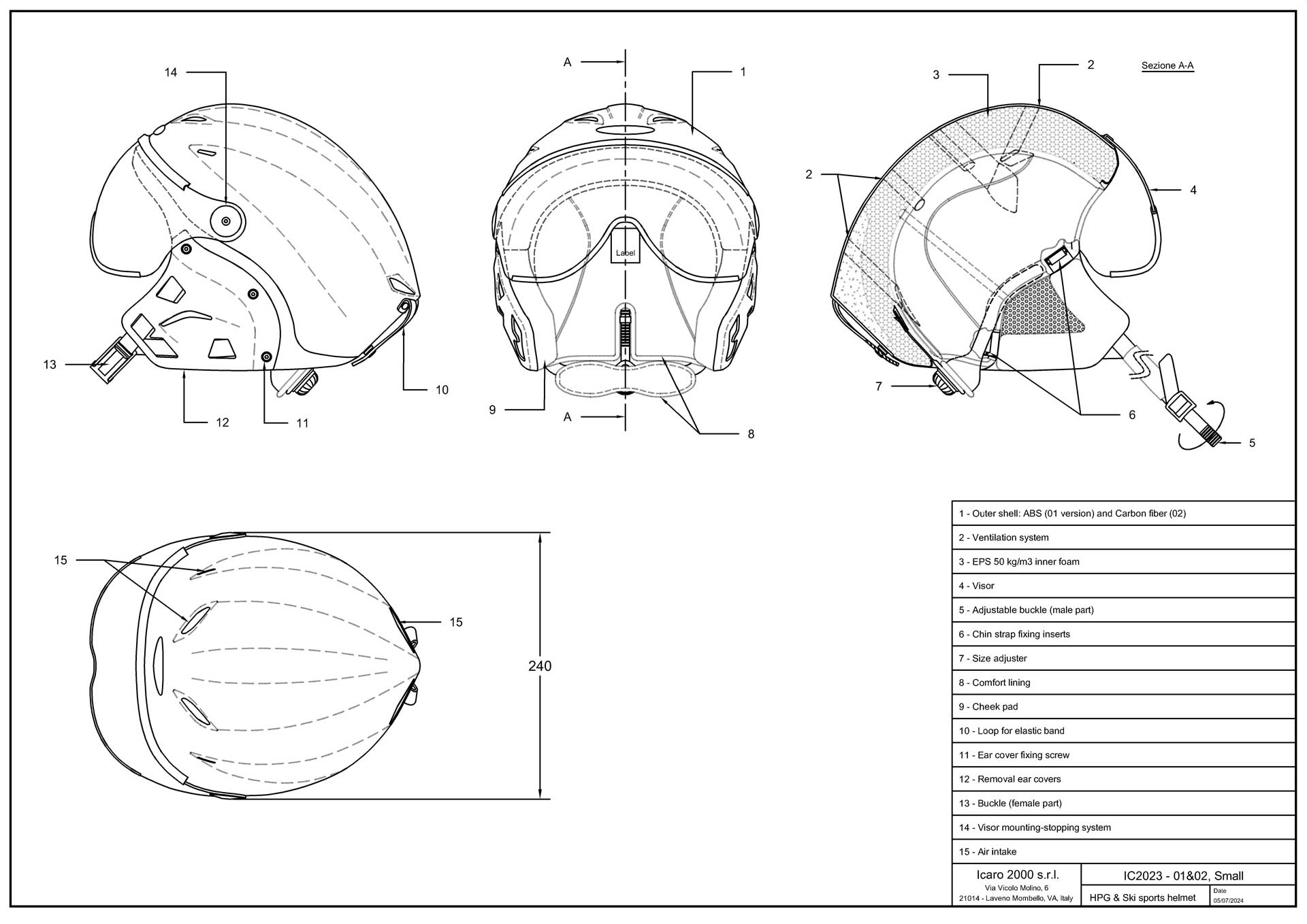

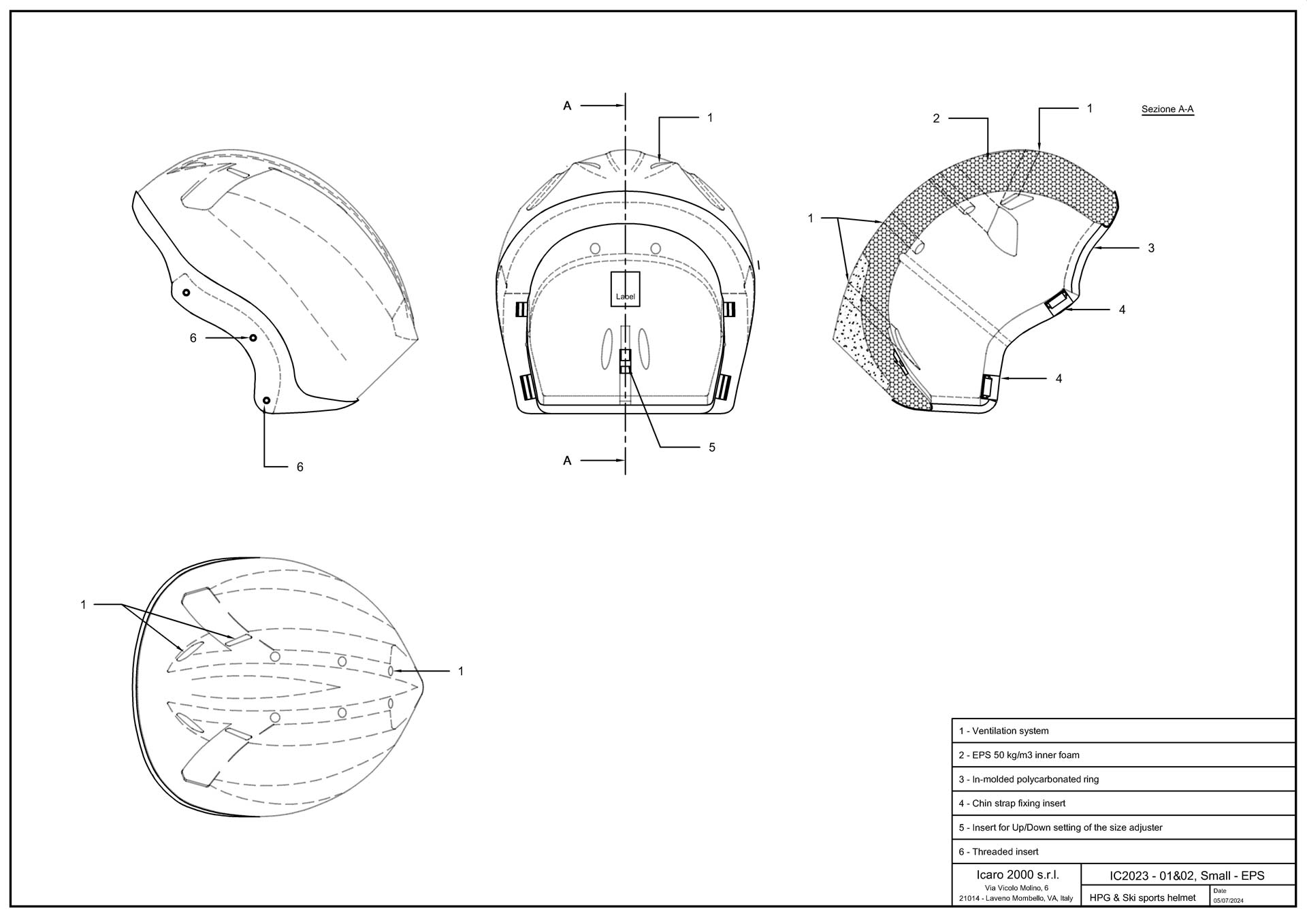

Icaro's new helmet Nevo has obtained certification for two very different activities, snow sports (EN 1077) and sport flying (EN 966). This innovative feature makes it a world first for this combination. It is a dual sport helmet that offers optimum safety, reduced weight, and distinctive style.

Read more...

Nevo, a 100% Italian masterpiece by designer Ignazio Bernardi and helmet specialist Felice Manzoni, is hallmarked by its spectacular appearance. It will undoubtedly become a visual highlight both in the sky and on ski slopes all over the world.

Nevo is available in many colours. Hang glider and paraglider pilots, skiers and snowboarders can choose their favourite look, according to their own individual tastes.

From snow to sky, Nevo is a ground-breaking helmet with Icaro's customary world-leading performance.

Ideal for sportspeople searching for the very best.

Carbon fibre shell

Matt or Gloss finish black or gray trim edge